-

Globe style bar stock needle valves are purpose designed valves for operation with any fluid up to 10,000 psi (689 bar) rating.

-

- Industry standard design for all instrumentation grade tubing

- Silver coated threads to reduce galling

- Back ferrule is treated with Suparcase technology to provide a strong mechanical grip on the tube

- Industry double ferrule design for system specifications

-

At Trelleborg Marine & Infrastructure, all our accessories are procured from pre-approved suppliers. We ensure that all our suppliers use the highest grade materials to produce the best quality products and we will test accessories quality when they cooperate with us and under quality management control by Trelleborg.

-

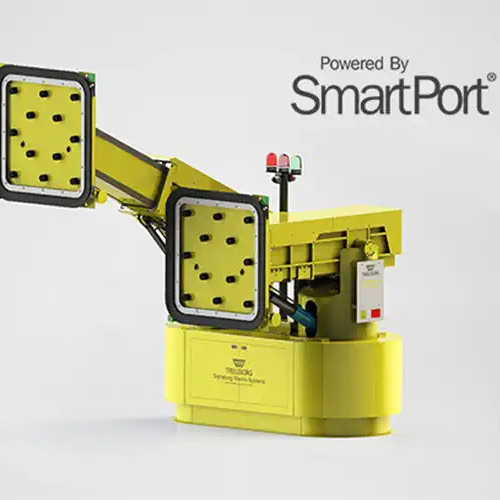

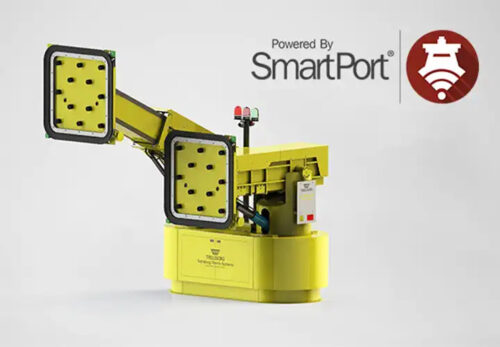

- Safer mooring operations – no mooring lines

- Minimizes vessel motions at berth

- Reduced mooring time increases port throughput and revenue

-

AutoMoor is Trelleborg’s rope-free, automated mooring system designed to make your berthing operations smarter, safer and more competitive. AutoMoor units eliminate mooring lines and are specifically designed to improve operational efficiency and enhance safety levels. Combining new vacuum pad and passive damping technology to rapidly attach to and secure a vessel at berth, the units are suitable for a range of environmental and berthing conditions. AutoMoor uses SmartPort technology to connect assets and to continuously monitor all mooring loads acting on the vessel at berth, it also provides live data to the operator to optimize day-to-day port and terminal operations.

-

Parker’s B Series ball valves, with a “free floating ” ball design, offer superior performance in a variety of pressure and temperature applications in process, and instrumentation applications.

-

This range of valves with fluoropolymer seals, available in compact, standard and lockable series, covers many industrial applications for which the fluids conveyed and working temperatures require this seal material.

-

Parker’s C Series check valves are designed for uni-directional flow control of critical fluids and gases.

-

- Size Availability: 1” – 12″; Working Pressure: MAX 250 psi

- Material: synthetic rubber, Thermoplastic, PTFE

- Approve: EN 13765:2003, EM, DNV, LLOYD, BV, ABS

-

Parker Autoclave’s pre-cut, coned-and-threaded tube nipples are provided in various sizes and lengths for rapid make-up. These are to be used with Parker Autoclave medium pressure valves and fittings for a secure connection.

-

- Three piece simple design to work on all instrumentation grade tubing

- Molybdenum Disulfide coated nuts to prevent galling and provide lubrication

- Single ferrule system treated with Suparcase technology to insure sealing

- Superior body seat surface finish to seal gases and liquids

- Single ferrule technology to provide excellent anti-vibration performance

- Excellent in high thermo cycling applications

-

-

-

Cast 2-Pce, split body, full port, soft seat, floating ball valve, anti-static, blow-out proof stem, locking facility, lever or gear hand wheel operated or actuated. Size Range: 15mm ~ 200mm Rating: Flanged RF Class 150 Design: ASME B16.34 Fire Safe: Fire Safe Design Face to Face: ASME B16.10 Flange Dimensions: ASME B16.5 Materials (ASTM): A351 CF8M Pressure Testing: API 598

-

Cast 1-Pce, end entry, reduced port, soft seat, floating ball valve, anti-static, blow-out proof stem, locking facility, lever or gear hand wheel operated or actuated. Size Range: 15mm ~ 250mm Rating: Flanged RF Class 150 & 300 Design: ASME B16.34 Fire Safe: API 607 Ed 5 / ISO 10497-5:2004 Face to Face: ASME B16.10 Flange Dimensions: ASME B16.5 Materials (ASTM): A216 WCB, A351 LCB, Super Duplex Pressure Testing: API 598

-

Name Floating Ball Valve Model Q341F Size 1/2″ ~ 10″ (DN15~DN250) Pressure 150LB ~ 300LB (PN10~PN40) Temperature -29°C~+250°C Body Material cast steel, stainless steel Drive Mode Handle operation, turbine operation, pneumatic operation, hydraulic operation, electric operation Applications Applicable to the switching of medium flow direction and the diversion or mixing of medium in water supply, petrochemical, metallurgy, mining, textile, energy, paper, food, steel and other pipeline systems -

- Size Availability: ¼” – 28″; Working Pressure: 1000 PSI

- Temp: -200o Celsius to 600o Celsius

- Material: SS304, SS316L, SS321 & Monel (upon request)

- Approve: EM, BS, DNV,…

-

Size Any Size or Model Thickness Any thickness Color natural Material NBR, EPDM, VITON, HNBR, Silicon Brand Alfa-laval, Tranter, GEA, SWEP, APV Application Glued or Clip type