We continuously push the limits of our Trelleborg Marine Fenders to ensure long-term performance and reliability.

With Trelleborg Super Cone’s unique proprietary rubber compound & cone fender geometry, our Trelleborg (SCN) Super Cone fenders are able to handle compression and shear far better than the old school “spool” shaped cell fenders.

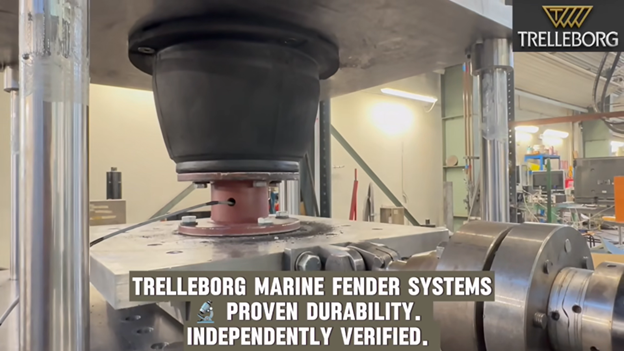

This recent test, conducted at an independent 3rd party laboratory, simulates long-term operational fatigue — validating Trelleborg’s rubber compounding integrity and the consistent performance of our fenders over time.

In this test, the smallest Trelleborg Super Cone Fender (available for sale) of equivalent rubber grade was subjected to up to 10,000 (ten thousand) cycles of:

• 50% axial compression (based on fender height)

• 30% horizontal shear (based on fender height)

and then followed by a final performance test to confirm that the fender still delivers its rated Energy Absorption and Reaction Forces, as published in our publicly available Trelleborg fender catalogues.

📏 What does this mean?

These 10,000 cycles simulate over 20 years of operational use — matching the expected design life of a marine fender, as outlined in both PIANC WG33 (2002), PIANC WG211 (2024) guidelines including the British Standard BS6349-4:2014.

You might wonder — Is this level of testing necessary?

✅ Absolutely. Marine fenders are often the only buffer between a vessel and your wharf structure. Their long term reliability directly impacts port safety and uptime.

And with Trelleborg Marine Fenders, you get:

• High durability

• Low maintenance

• Reduced replacement frequency

• Lowest Total Cost of Ownership (TCO)

We’ve been testing our fenders at independent test laboratories to 10,000-cycle durability tests since 2015 — and we’re not stopping anytime soon. It’s our commitment to giving our Customers lasting confidence in the performance of their Trelleborg Marine Fender Systems installed at their wharf.

🧪 Whether tested in-house or independently, Trelleborg Marine Fenders consistently meet and exceed the highest global durability standards.

📌 Engineered for reliability. Built for the world’s most demanding marine environments.