Maximize use of your infrastructure To increase profitability, shipping vessels are getting larger. At the same time, it is very difficult to expand ports in many locations, which in turn results in serious safety issues as well as a lack of berth space. Bottleneck effects are worsened by the fact that vessels’ estimation of arrival times is generally very poor. With some 45 percent of all container vessels delayed by more than eight hours, the potential for increased efficiency is huge.

-

-

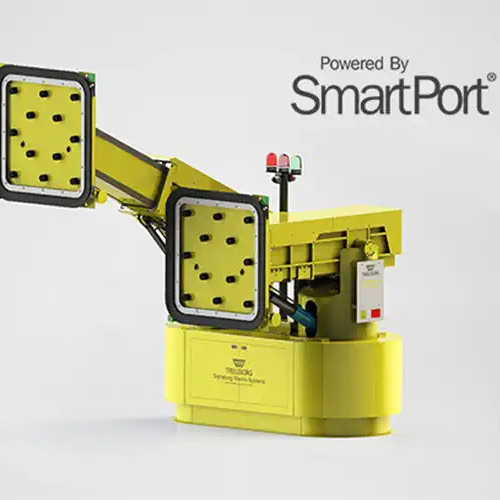

- Safer mooring operations – no mooring lines

- Minimizes vessel motions at berth

- Reduced mooring time increases port throughput and revenue

-

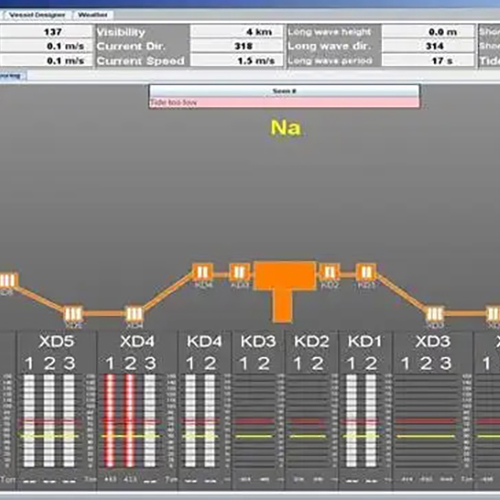

- MetOcean parameter measurement in real time, local or remote

- Deployment and retrieval systems optimized to your site

- Integration into Approach, Docking and Mooring Systems

-

- Accurate measurement of local site conditions

- Hazardous or non hazardous weather Stations

- Integrated into Docking & Mooring Systems or as standalone

-

-