-

-

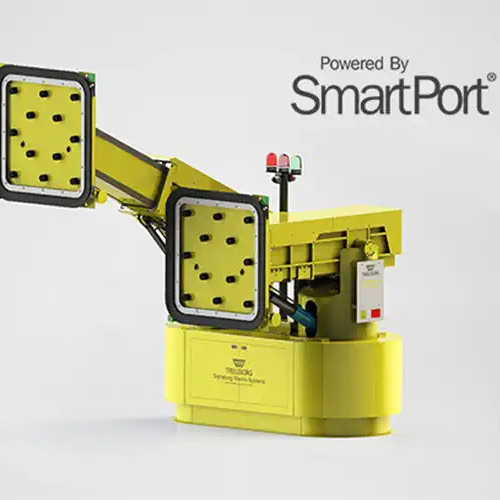

- Safer mooring operations – no mooring lines

- Minimizes vessel motions at berth

- Reduced mooring time increases port throughput and revenue

-

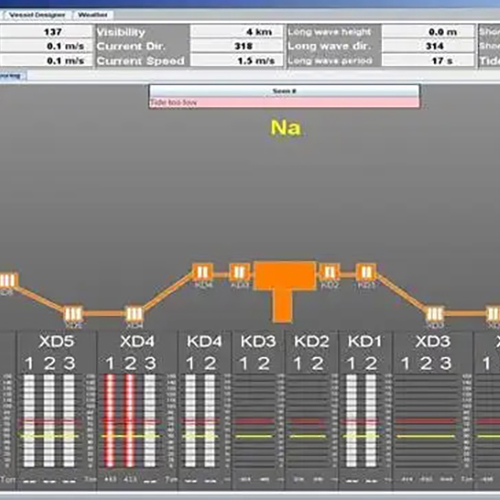

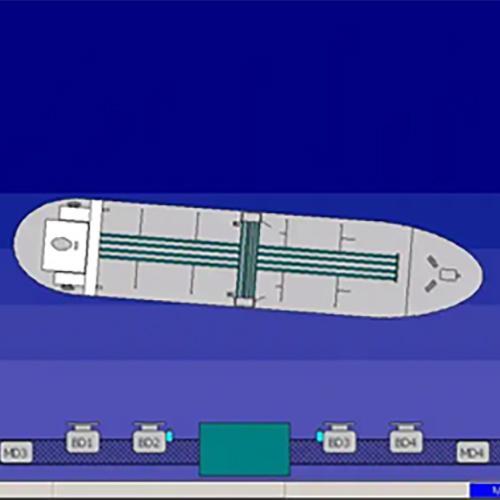

- MetOcean parameter measurement in real time, local or remote

- Deployment and retrieval systems optimized to your site

- Integration into Approach, Docking and Mooring Systems

-

- Accurate measurement of local site conditions

- Hazardous or non hazardous weather Stations

- Integrated into Docking & Mooring Systems or as standalone

-

-

-

-

-

- Class 150 to Class 2500

- Size Range 1/2” thru 24” (Class Dependent)

- Full and Reduced Bore

- Body Wall Thickness ASME B16.34, Forged or Cast Versions

- End Connections: RF, RTJ, BW, SW, NPT, BSP, Special

- Fire-Safe Design API 607

- Emergency Sealant Injectors as Standard

- Anti-Static Device and Live-Loaded Packing

- Blowout Proof, Low Torque Guided Stem Design

- Fugitive Emissions ISO 15848

- Wide Range of Soft Seat and Metal Seat Options

- Manual, Electric, Pneumatic, or Electro-Hydraulic Operators Available

- Custom Face-to-Face Lengths Available per Customer Requirement

-

Name Floating Ball Valve Model Q341F Size 1/2″ ~ 10″ (DN15~DN250) Pressure 150LB ~ 300LB (PN10~PN40) Temperature -29°C~+250°C Body Material cast steel, stainless steel Drive Mode Handle operation, turbine operation, pneumatic operation, hydraulic operation, electric operation Applications Applicable to the switching of medium flow direction and the diversion or mixing of medium in water supply, petrochemical, metallurgy, mining, textile, energy, paper, food, steel and other pipeline systems -

Cast 1-Pce, end entry, reduced port, soft seat, floating ball valve, anti-static, blow-out proof stem, locking facility, lever or gear hand wheel operated or actuated. Size Range: 15mm ~ 250mm Rating: Flanged RF Class 150 & 300 Design: ASME B16.34 Fire Safe: API 607 Ed 5 / ISO 10497-5:2004 Face to Face: ASME B16.10 Flange Dimensions: ASME B16.5 Materials (ASTM): A216 WCB, A351 LCB, Super Duplex Pressure Testing: API 598

-

Cast 2-Pce, split body, full port, soft seat, floating ball valve, anti-static, blow-out proof stem, locking facility, lever or gear hand wheel operated or actuated. Size Range: 15mm ~ 200mm Rating: Flanged RF Class 150 Design: ASME B16.34 Fire Safe: Fire Safe Design Face to Face: ASME B16.10 Flange Dimensions: ASME B16.5 Materials (ASTM): A351 CF8M Pressure Testing: API 598

-

Size Any Size or Model Thickness Any thickness Color natural Material NBR, EPDM, VITON, HNBR, Silicon Brand Alfa-laval, Tranter, GEA, SWEP, APV Application Glued or Clip type -

- Size Availability: 1/8″ to 3″; Working Pressure: MAX 2300 BAR

- Material: synthetic rubber, Thermoplastic, PTFE

- Approve: ABS, BV, DNV, GL, GOSR-R, KRS, LR, RINN

-

- Size Availability: 2” – 28″; Range: Max 20 bar

- Material: NBR, EPDM, PTFE, SST, FABRIC

-

- Size Availability: 5” to 24”; Working Pressure: 3000 PSI.

- Our rubber hose,produced on rigid mandrel, can be assembly according to customer’s requirement and can be fitted with any type of coupling.

- Approve: DNV, LLOYD, RINA,…

-

- Size Availability: 1/4″ to 20″; Working Pressure: 150 PSI to 1000 PSI

- Medium: air, steam, oil, water, chemical, sand blast, multipurpose…

-

- Size Availability: ¼” – 28″; Working Pressure: 1000 PSI

- Temp: -200o Celsius to 600o Celsius

- Material: SS304, SS316L, SS321 & Monel (upon request)

- Approve: EM, BS, DNV,…

-

- Size Availability: 1” – 12″; Working Pressure: MAX 250 psi

- Material: synthetic rubber, Thermoplastic, PTFE

- Approve: EN 13765:2003, EM, DNV, LLOYD, BV, ABS

-

Parker’s C Series check valves are designed for uni-directional flow control of critical fluids and gases.

-

This range of valves with fluoropolymer seals, available in compact, standard and lockable series, covers many industrial applications for which the fluids conveyed and working temperatures require this seal material.

-

Parker’s B Series ball valves, with a “free floating ” ball design, offer superior performance in a variety of pressure and temperature applications in process, and instrumentation applications.

-

Globe style bar stock needle valves are purpose designed valves for operation with any fluid up to 10,000 psi (689 bar) rating.

-

Parker Autoclave’s medium pressure tubing is capable of operating to 20,000 psi (1379 bar) and range in size from 1/16″ to 1 1/2″ tube size. Standard tubing is available in cold worked stainless steel.

-

Parker Autoclave’s low pressure tubing is capable of operating to 15,000 psi (1034 bar) and range in size from 1/16″ to 1/2″ tube size. Standard tubing is available in 316 and 304 stainless steel.