- Available in socketweld, buttweld and automatic buttweld connections

- Manuafactured to meet ASME Section III, and ANSI B31.1 and B31.7 codes

- Permanent, leak free connection

- For critical application and high temperatures such as steam

-

-

Parker Autoclave’s medium pressure tubing is capable of operating to 20,000 psi (1379 bar) and range in size from 1/16″ to 1 1/2″ tube size. Standard tubing is available in cold worked stainless steel.

-

Parker Autoclave’s low pressure tubing is capable of operating to 15,000 psi (1034 bar) and range in size from 1/16″ to 1/2″ tube size. Standard tubing is available in 316 and 304 stainless steel.

-

- Class 150 to Class 2500

- Size Range 1/2” thru 24” (Class Dependent)

- Full and Reduced Bore

- Body Wall Thickness ASME B16.34, Forged or Cast Versions

- End Connections: RF, RTJ, BW, SW, NPT, BSP, Special

- Fire-Safe Design API 607

- Emergency Sealant Injectors as Standard

- Anti-Static Device and Live-Loaded Packing

- Blowout Proof, Low Torque Guided Stem Design

- Fugitive Emissions ISO 15848

- Wide Range of Soft Seat and Metal Seat Options

- Manual, Electric, Pneumatic, or Electro-Hydraulic Operators Available

- Custom Face-to-Face Lengths Available per Customer Requirement

-

-

-

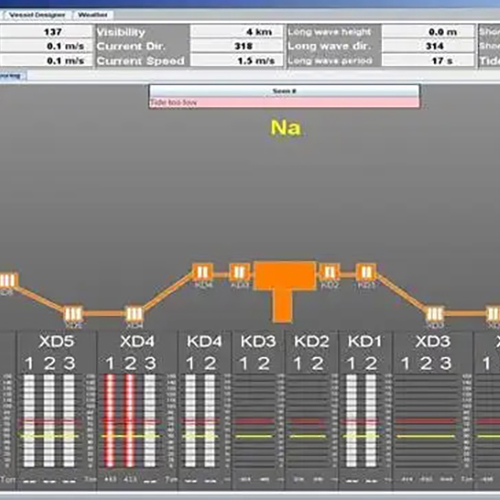

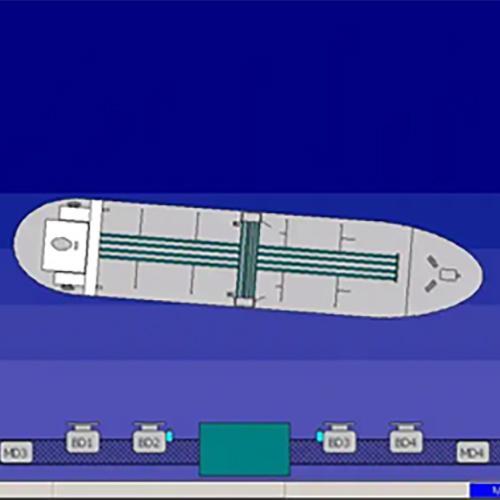

As our industry continues to face the challenges of globalization and increasing scale and utilization of vessels, we must continuously look for ways to improve efficiencies. Shipping companies and port operators must look for smarter ways to deliver against these expectations. SmartPort by Trelleborg powers the critical interface between ship and port, on land and at sea. Building on Trelleborg’s history of engineering ingenuity and sector knowledge, with a keen eye on data capture and management, and technology-driven insight, SmartPort technologies can increase efficiencies, improve safety and improve ROI for ports and vessels alike.

-

-

-

- Size Availability: 1/8″ to 3″; Working Pressure: MAX 2300 BAR

- Material: synthetic rubber, Thermoplastic, PTFE

- Approve: ABS, BV, DNV, GL, GOSR-R, KRS, LR, RINN

-

-

- Easy and fast to deploy

- Very low reaction and hull pressure

- Maintains large clearances between hull and structure

-

- Size Availability: 2” – 28″; Range: Max 20 bar

- Material: NBR, EPDM, PTFE, SST, FABRIC

-

Correct instrument tubing selection and installation are key ingredients in building leak-free reliable tubing systems. Utilising Parker’s instrument grade tube with its range of fittings will help with your asset integrity program.